INFRASTRUCTURE

Infrastructure

OUR BUILDING BlOCKS

At Vimson Coatings, our building blocks are designed to Go Global . But for us, going global means more than just exporting our products to other countries. It’s about being able to understand our customer’s needs and meet their requirements to the best of our abilities wherever they are, at any time of the day – through high quality and speedy delivery .

Our products are designed with new-world ambitions, and we build them in a way that they scale across time zones and cultures. Our building blocks are flexible enough to be customised, so they fit the local market needs of that particular city or region.

Our own plant in Nashik , manufacturing label stock and release liners, is a massive area equipped with high-end machines. It is our machinery that helps us produce superior products quite efficiently by enhancing productivity and reducing the cost of production.

Fully equipped lab with all state of the art testing equipment to ensure consistent quality and to conduct extensive research for developing new products.

OUR Equipments

Take a closer look at our equipments and how they function:

Innovating through technology

With a focus on becoming a leading manufacturer in label stock and release liners, we constantly look for ways to stay ahead of industry trends and deliver new and innovative solutions to our customers.

We don’t just come up with a new idea or innovation and then stop there. We focus on developing that idea, checking if it works perfectly, looking at its potential for sustainability, and then doing our best to make it happen – in the very best possible way for our customers.

Our focus is on continually investing in a range of innovative technologies and services to deliver products that are easy to use, cost-effective and sustainable.

Where safety takes precedence

Safety is at the heart of everything we do in our business. We believe health and safety is a fundamental right of employees and we always strive to make them an integral part of our workplace culture. We take the safety and well-being of all our employees seriously, by developing procedures and protocols to protect them from potential hazards in their work environment.

We ensure that every employee leaves their workplace safe and sound, and for that, we work together to keep everyone safe on the job site. For us, that means having regular safety training, implementing stringent safety standards, and proactively mitigating hazards.

Sustainability at its core

With a focus on becoming a leading manufacturer in label stock and release liners, we constantly look for ways to stay ahead of industry trends and deliver new and innovative solutions to our customers.

We are a company of innovators who turn ideas into realities. While we believe that lasting changes require commitment and dedication, we are focused on putting our collaborative efforts into carving a name for ourselves in the most sustainable ways.

When it comes to sustainability, we at Vimson Coatings are all about reducing our carbon footprints, increasing customer satisfaction, and meeting their demands – all the while improving our products’ eco-credentials.

quality that matters

We take quality very seriously and have a rigorous quality control system in place. You can be sure that our products are of great quality. Quality is our hallmark and dominates all of our production processes . From raw material testing and online testing to finished product testing – we monitor every step very meticulously.

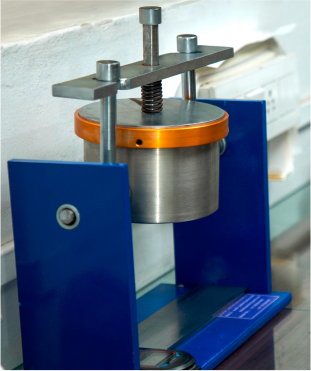

Our aim is to ensure that customers are satisfied with our products , so we make sure to test every step of the production process. We are always willing to listen to their requests because we never stop improving our products and services. Some of our best quality testing equipment includes:

- Digital weighing scale for checking GSM of the substrate with high accuracy

- Lab Oven equipment for checking the adhesive’s solid content

- Loop tack tester to check the initial tack of label stocks

- Shear tester to check the cohesive strength of the adhesive

- Rolling ball tester to check the tack of the adhesive

- Peel tester and release value tester to measure peel and release value of the product